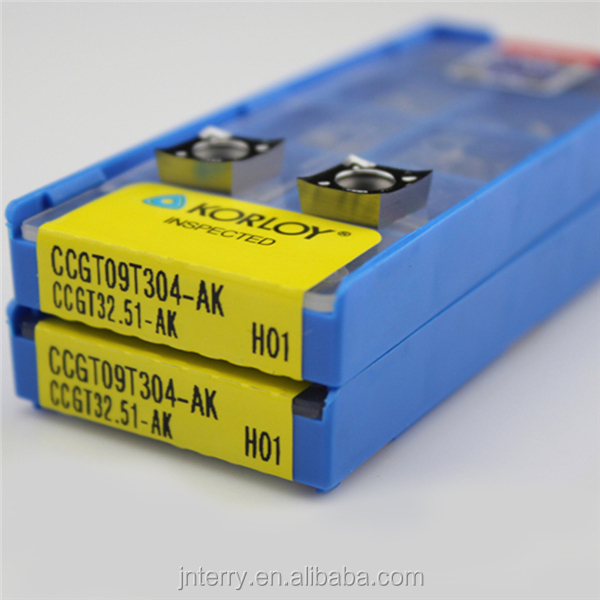

TNMG160404-HA H01 Korloy Carbide Cutting Tools CNC Turning Inserts

Model:TNMG160404-HA H01

Standard:

Korloy Carbide Cutting Tools CNC Turning Inserts

Advantages:

Best Price: Our prices are more competitive than other suppliers'. And the more you order, the more discount you will get.

Short Delivery: We will arrange the order for you after the payments. The strong stock will guarantee the delivery item for you.

High Quality:The effiency and high- performance cutting will help you in good mood!

Technical help:Our engineers can help to design technical plan for CNC cutting machine cutting tools assembly, and offer after-sales service professionally.

Features of Korloy inserts:

1).Original KORLOY brand carbide inserts manufacturer in korea ;

2).Stable machining due to strong toughness and high hardness that reduces fracture by chipping;

3).Excellent wear resistance due to special PVD/CVD coating film;

4).High hardness substrate ensures long tool life in high speed milling;

5).Tough carbide, smooth coating for improved tool life;

Specifications of Korloy inserts:

1).Brand: Korloy;

2).Place of Origin: carbide inserts manufacturer in korea;

3).Material: Tungsten Carbide/Hard Alloy/Cermet;

4).Delivery: Short;

5).MOQ: 10 pieces (1 box);

6).Application: Internal & external turning for steel, stainless steel ,cast iron, aluminium and any other hardmetal workpiece;

7).Package: Original plastic box.

Advantages of Korloy inserts:

- Competitive Price

- Good Performance

- Short Delivery Time

- Quality guaranteed

- Small Orders Acceptable

- Economical and productive insert options are based on individual cutting conditions (roughing, semi-finishing and finishing)

Photos for Korloy Inserts:

KORLOY INSERTS MATERIAL GRADES:

|

Grades |

Application |

|

|

NC5330 |

stainless Steel/General Cutting for Mild Steel & Forging Steel |

|

|

NCM325 |

For high speed milling of steel and stainless steel |

|

|

NCM335 |

For interrupted and rough milling of steel and stainless steel |

|

|

PC3600 |

Milling grade for medium and roughing of steel |

|

|

PC3545 |

Milling grade for medium and roughing of steel |

|

|

PC5300 |

High efficiency during machining of carbon steel / cast iron / stainless steel / HRSA |

|

|

PC8110 |

PVD Coated grade for stainless steel and HRSA. |

|

|

PC6510 |

High speed milling grade for cast iron and aluminum. |

|

|

PC9530 |

Milling grade for cast iron and aluminum in medium to low cutting speed |

|

|

PC210 |

Suitable for medium/low speed cutting of steel, stainless steel and super alloy |

|

|

PC203F |

Suitable for high speed cutting of steel |

|

|

PC205F |

Solid drill(under Ø20) for steel, stainless steel and super alloy |

|

|

PC210C |

Medium to high speed machining of copper |

|

|

PC220 |

General cutting for steel |

|

|

PC210F |

High speed milling grade for hardened steel , cast iron, and stainless steel(Laser Mill) |

|

|

NC3010 |

High speed cutting for steel |

|

|

NC3220 |

For medium machining of steel |

|

|

NC3120 |

Medium to roughing for steel |

|

|

NC3030 |

For general cutting, interrupted cutting and roughing operations in steel and stainless steel |

|

|

NC9025 |

stainless Steel/General Cutting for Mild Steel & Forging Steel |

|

|

NC500H |

|